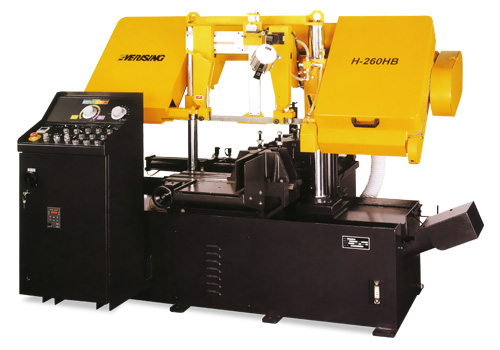

NC Control - Column Type

This series of automatic sawing machine combines large capacity with a powerful drive system. Fully equipped with NC automatic controls for fast set-up and maximum production, it’s the ideal machine for cutting structural, tubing and solids in mild steel. Constructed using industrial grade components and materials it will stand up to years of grueling service in any demanding fabrication shop or machine shop.

| Parameter | Unit |

| Working capacity(solid round bar) | mm |

| Working capacity(solid square bar) | mm |

| Blade size | mm |

| Hydraulic pump motor | HP |

| Coolant pump motor | HP |

| Index length | mm |

| Floor space(LxW) | mm |

| Machine weight | kg |

H-700HANC H-1070HANC 700 800 x 700 8000 x 54 x 1.6 3 1/4 500 4100 x 2300 7000 700 1000 x 700 8800 x 67 x 1.6 3 1/2 500 4500 x 2300 8500

Digital readout index

Index length is easily set in seconds with a hand wheel mounted to the front of the machine. Minimum increment is 0,025 mm.

Roller bearing + carbide guide blocks

Roller guides serve as a pre guides to take the twist out of the blades before the blade goes through the spring loaded and flat carbide side guides with internal coolant.

Infinitely variable speed

Blade speed is regulated by hand wheel within easy reach of the operator. Speeds are infinitely variable to handle a full range of materials from nickel based alloys to aluminum.

Free standing roller table

The roller stock table includes 2 sets of double adjustable vertical guide rollers and slide bars: used with nesting fixture attachment.

Programmable control (optional)

Programmable control allows you to program 9 different jobs with job number, number of cuts and cutting length, eliminating extensive set-up time. The NC controller also incorporates automatic kerf compensation.

Split front vise

This unique vise design permits the workpiece to be automatically indexed to a barred remnant of 50 mm. The vise securely clamps the workpieces on both sides of the cut thus drop-off the burrs. This design is most suitable for nesting or bundle cutting and is ideal for cutting short length pieces.

Hydraulic blade tension

Hydraulically operated full stroke control for the dual vise clamping system. This unique device permits the workpiece to be automatically indexed to reduce remnant size. The vise securely clamps the workpiece on both sides of the cut, thus minimizing drop-off burrs.

Automatic chip conveyor (optional)

By removing chips from the cutting area, chip build-up is eliminated and maximum productivity is enable.

Nesting fixture for bundle cutting

A nesting fixture set consists of hydraulic clamps which may be mounted to both the index and the front vises. This makes it possible to cut multiple pieces at one time.